Minwax High Performance Wood Hardener:

Approximately $9/can at Home Depot.

Ever since I saw this product in Home Depot a couple of years ago, I've wonder how it would work on MDF. Well, this past weekend I set out to find out.

Not super scientific, but I took four scraps of 3/4" thick MDF that I had in my garage. Two were the light brown MDF from Home Depot and two were from the darker brown MDF from Lowes. The samples were approximately 3" wide by 9" long. I set aside one sample from each brand to be used as a control. Then I prepared the two remaining samples by applying several coats of the Minwax Wood Hardener. I poured about 1/2" into a small plastic cup and just kept applying the wood hardener to all sides until it was gone. I didn't really put much effort into making sure that each side got the exact same amount. The wood hardener went on quickly and appeared to be absorbed rapidly into the surface. It took probably 15 minutes to apply. I may have been able to apply more and have it absorbed.

After allowing the samples to dry about 4 hours, the surface became very hard. Trying to bend the samples, the untreated samples feel like they bend very slightly, while the treated samples feel much stiffer and can't be bent.

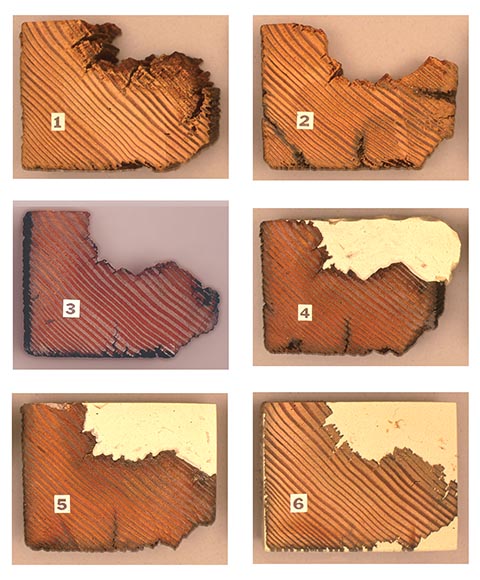

I then cut the samples in half and trimmed the edges to view the wood hardener penetration. You could easily see the color change where the wood hardener penetrated. The penetration appeared to be very uniform in depth and measured approximately 1/8". I'm not sure if it is just the difference in the original color of the MDF, but the wood hardener appears to have penetrated the lighter MDF from Home Depot more thoroughly.

Four Samples

Dark MDF Control, Dark MDF Treated, Light MDF Control, Light MDF Treated

Dark MDF Treated, Inside Faces

Light MDF Treated, Inside Faces

Based on what I've seen, it appears that Minwax Wood Hardener is cheap, easy to apply, and can significantly increase the stiffness and strength of MDF. I can only see this as a good thing for building speakers as we try to stiffen up boxes to reduce resonances. It probably is also a good product to seal the MDF for painting or whatever.

Tomorrow, I'm going to call a testing lab that I work with a lot and see if they'll do me a favor and break these samples. I would love to have real test results. I'll also probably do some experiments with my three surrounds currently in production to see how it takes paint and such.

Approximately $9/can at Home Depot.

Minwax High Performance Wood Hardener is a quick-drying liquid formulated to strengthen and reinforce decayed or rotting wood. Minwax® High Performance Wood is made up of solvents that carry resin deep into the pores of the wood where they evaporate and leave behind hardened resin resulting in hardened wood.

Directions:

1. Completely remove decayed and very soft, crumbly wood until you reach reasonably sound wood. Wood should be dry, free from dirt, grease, oil and loose paint particles. 2. Shake can well; apply Minwax® High Performance Wood Hardener with a disposable bristle brush to the softened wood to completely saturate the area. 3. For strength, apply several coats in quick succession until a shiny surface appearance is obtained. 4. Allow to harden for 2-4 hours before filling void with Minwax® High Performance Wood Filler. 5. Sand, paint, or stain if desired.

1. Completely remove decayed and very soft, crumbly wood until you reach reasonably sound wood. Wood should be dry, free from dirt, grease, oil and loose paint particles. 2. Shake can well; apply Minwax® High Performance Wood Hardener with a disposable bristle brush to the softened wood to completely saturate the area. 3. For strength, apply several coats in quick succession until a shiny surface appearance is obtained. 4. Allow to harden for 2-4 hours before filling void with Minwax® High Performance Wood Filler. 5. Sand, paint, or stain if desired.

Not super scientific, but I took four scraps of 3/4" thick MDF that I had in my garage. Two were the light brown MDF from Home Depot and two were from the darker brown MDF from Lowes. The samples were approximately 3" wide by 9" long. I set aside one sample from each brand to be used as a control. Then I prepared the two remaining samples by applying several coats of the Minwax Wood Hardener. I poured about 1/2" into a small plastic cup and just kept applying the wood hardener to all sides until it was gone. I didn't really put much effort into making sure that each side got the exact same amount. The wood hardener went on quickly and appeared to be absorbed rapidly into the surface. It took probably 15 minutes to apply. I may have been able to apply more and have it absorbed.

After allowing the samples to dry about 4 hours, the surface became very hard. Trying to bend the samples, the untreated samples feel like they bend very slightly, while the treated samples feel much stiffer and can't be bent.

I then cut the samples in half and trimmed the edges to view the wood hardener penetration. You could easily see the color change where the wood hardener penetrated. The penetration appeared to be very uniform in depth and measured approximately 1/8". I'm not sure if it is just the difference in the original color of the MDF, but the wood hardener appears to have penetrated the lighter MDF from Home Depot more thoroughly.

Four Samples

Dark MDF Control, Dark MDF Treated, Light MDF Control, Light MDF Treated

Dark MDF Treated, Inside Faces

Light MDF Treated, Inside Faces

Based on what I've seen, it appears that Minwax Wood Hardener is cheap, easy to apply, and can significantly increase the stiffness and strength of MDF. I can only see this as a good thing for building speakers as we try to stiffen up boxes to reduce resonances. It probably is also a good product to seal the MDF for painting or whatever.

Tomorrow, I'm going to call a testing lab that I work with a lot and see if they'll do me a favor and break these samples. I would love to have real test results. I'll also probably do some experiments with my three surrounds currently in production to see how it takes paint and such.

unk:

unk:

Comment