I can't seem to stay focused these days... building sealed statements, two amps, and a buffer all at the same time. Anywho... here's a thread for the latest item. A pair of CJDs rs150 . I need a pair of smaller speakers for the bedroom. They'll probably be driven from a chip amp (that I've actually completed already) using my iphone as a source!  h:

h:

I got the tweeters in the pawn shop and the woofers aren't that much to begin with so I just bought them.

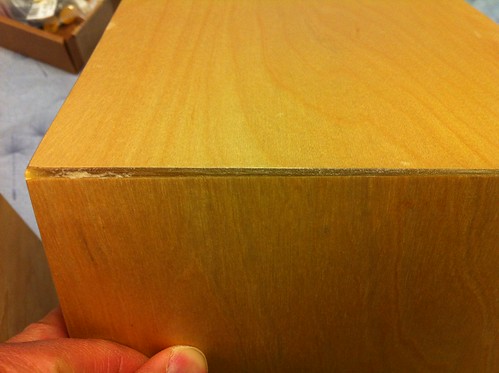

I'm planning on doing every side but the front as a a simple birch plywood build with mitered and biscuited corners. Might need to clean up the corners with a 3/8" bevel as a design feature (I'm a sucker for the laminate look for some reason). Thinking a basic hand rubbed tung oil finish similar to many of my other builds.

The front will be MDF with beveled corners as well 1/2", painted a flat or satin black.

h:

h: I got the tweeters in the pawn shop and the woofers aren't that much to begin with so I just bought them.

I'm planning on doing every side but the front as a a simple birch plywood build with mitered and biscuited corners. Might need to clean up the corners with a 3/8" bevel as a design feature (I'm a sucker for the laminate look for some reason). Thinking a basic hand rubbed tung oil finish similar to many of my other builds.

The front will be MDF with beveled corners as well 1/2", painted a flat or satin black.

Comment