So in this months Stereophile, in an interview with the guy from Magico, they spend some time discussing cabinets. He builds his out of extruded aluminum, and they weigh hundreds of pounds. His view on MDF is that it is not rigid enough, doesn't make a great launching point for sound waves, allows driver bolts to loosen over time, and must be the worst material for building speaker cabinets. If a person were stuck with wood as a construction material, what do you think would represent a construction technique that represented the "ultimate" wooden cabinet?

Best DIY speaker cabinet

Collapse

This topic is closed.

X

X

-

Ultimate? That's beyond me to know what the very best is, but a combo of plywood, MDF, sound deadener, and anything else that adds mass would be better than any single material.- Bottom

-

How else can he sell his overpriced aluminum enclosures? People will do whatever it takes to market a product even if it is based on myths. The thing is, those baseless statements eventually catch up with you after people/consumers do their research and then later realize how much BS there is in the hifi world. It definitely doesn't help the ethical companies out there.Originally posted by OperandiThe "worst material"???

I would say that statement right there eliminates whatever little creditability he had. :roll:.- Bottom

Comment

-

> doesn't make a great launching point for sound waves

I don't want my *enclosures* to be a "launching point" for sound waves . . . period.

The "best" wood (wood only) enclosure would have to be curved gluelam (translam), with plenty of internal bracing. We've seen some very nice examples of that right here. Second would be more conventional box construction but with more than the usual internal bracing (to prevent panel resonances).

Screws can pull out of MDF, or loosen, eventually, maybe. Compressable gasket reduces the chance, or the importance, of any loosening. Hurricane nuts all but eliminate it.- Bottom

Comment

-

Best DIY speaker Cabinet

So....even if this guy is full of crap, (I am currently enjoying my all MDF DIY speakers right now) would some laminated comination of BB ply and MDF make for a more inert cabinet? Should my next project be laminations of 1/2 inch BB play and 1/2 inch MDF to a 2 inch thickness? Would I notice a difference?- Bottom

Comment

-

Kind of funny he says that as a lot of his speakers use wood. I don't doubt that his aluminum cabinets might be awesome but for the weight and price and everything else I don't think they are going to be all that much better then a nice translam or something.- Bottom

Comment

-

You guys do realize this is Magico, the company with the Mini that uses the stacked lamination curved enclosure, right? The people that have made those here, copied Magicos design.Originally posted by Deward Hastings> doesn't make a great launching point for sound waves

I don't want my *enclosures* to be a "launching point" for sound waves . . . period.

The "best" wood (wood only) enclosure would have to be curved gluelam (translam), with plenty of internal bracing. We've seen some very nice examples of that right here. Second would be more conventional box construction but with more than the usual internal bracing (to prevent panel resonances).

Screws can pull out of MDF, or loosen, eventually, maybe. Compressable gasket reduces the chance, or the importance, of any loosening. Hurricane nuts all but eliminate it.

His complaint isn't with wood. His enclosures are not 100% aluminum. His complaint is with MDF. Put a screw into mdf, then put a screw into baltic birch (his material of choice with aluminum) and see which one you can strip out easier. Even if you use a T nut or a hurricane nut or whatever, you still have an easier time tearing out the mdf.

I would be careful making claims like this:

"but a combo of plywood, MDF, sound deadener, and anything else that adds mass would be better than any single material."

that may not necessarily be true.- Bottom

Comment

-

The ideal cabinet is one that does not resonant at any given frequency inside the operational range. I assume the aluminum cabinet pushes the resonant frequency high enough in the frequency range such that the acoustic power of the drivers does not excite it.

If a cabinet has a resonant frequency inside the desired operational range, then it would be nice to dampen it's response. This is way MDF is popular (besides cost), it is more damp then stiffer materials. Think metal cones vs. paper cones.

Composite structures are also popular (say plywood + MDF) because you can combine stiffness (plywood) with damping (MDF).- Bottom

Comment

-

Oops. I was meaning any single material I mentioned. Combo's are always good because each material will have it's own resonance, which can be damped by the other material.Originally posted by Rolex"but a combo of plywood, MDF, sound deadener, and anything else that adds mass would be better than any single material."

that may not necessarily be true.- Bottom

Comment

-

It gets to be a complicated question with complicated answers...Originally posted by looneybomberOops. I was meaning any single material I mentioned. Combo's are always good because each material will have it's own resonance, which can be damped by the other material.

I did a lot of reading and netsearching on the subject. There's some good and interesting info and experiments out there to find.

What seems to be the deal with making composite layers or constrained layer boxes, is that there's a certain ratio of best result... you can have too much or too little of a different material with lesser results. So, different sizes of panels in a box would need different ratios. And, it also depends on how thick, how flexable, how lossy, the various layers are. So, to do it really well, you probably need to measure how it's working.

But overall, at a basic level, it's not too picky.. a stiffer layer with a lossy layer behind it will be damped more. Thicker is stiffer. Brace your panels well, smaller vibrating areas radiate less sound, etc... Good construction practices will get you a large percentage of possible result.- Bottom

Comment

-

Using an inner core of 3/4 MDF and 3/4 Ply on the outside makes for a very well damped box. It is my prefered method. Wood screws should only be used to hold the box together while the glue dries so who cares if it strips Michael

Michael

Chesapeake Va.- Bottom

Comment

-

This is not the issue with screws stripping. It is where the driver is mounted to that cabinet that this becomes an issue. Even threaded inserts can strip easliy in mdf. Not so with baltic birch. Meaning, not nearly as easy. Can still happen though.Originally posted by buggersUsing an inner core of 3/4 MDF and 3/4 Ply on the outside makes for a very well damped box. It is my prefered method. Wood screws should only be used to hold the box together while the glue dries so who cares if it strips

- Bottom

Comment

-

jk,

you might find this interesting if you haven't already seen it.

its not in English but online translators are sufficient to get the material names that aren't obvious.- Bottom

Comment

-

I can live with the cast aluminum front baffles, and think the issue of screws loosening up in MDF is just due to poor execution.Originally posted by jkruegerSo in this months Stereophile, in an interview with the guy from Magico, they spend some time discussing cabinets. He builds his out of extruded aluminum, and they weigh hundreds of pounds. His view on MDF is that it is not rigid enough, doesn't make a great launching point for sound waves, allows driver bolts to loosen over time, and must be the worst material for building speaker cabinets. If a person were stuck with wood as a construction material, what do you think would represent a construction technique that represented the "ultimate" wooden cabinet?

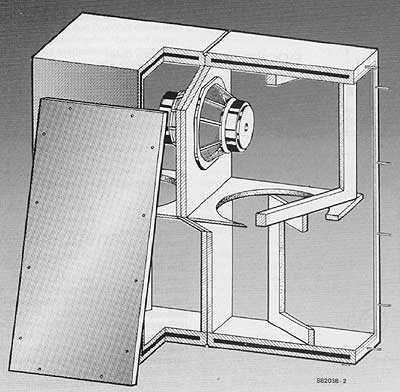

But what I wonder is: In a high end design such as this, why wen't the woofers anchored to by baffle by the magnet assembly. The pic in the article show the driver mounted with small brackets over the edge of the driver flanges. Surely the drivers would get a better 'launch' if physically tied to the baffle by their center of mass (the magnet assy) rather than the flange. Since these are custom castings anyway, I would think it would have been relatively easy to cast in the necessary attachment flanges.

C- Bottom

Comment

-

Thanks for the replys. I have tightened my own screws once since completing my last build, and they mostly needed half a turn. It seemed that the mid screws needed the most attention. I can hardly believe that they will eventually pull out or become a problem though. My current cabinets are 100% MDF. I think that next time I build something important for myself, I will use some sort of multi material lamentation.- Bottom

Comment

-

Yup.Originally posted by Curt CBut what I wonder is: In a high end design such as this, why wen't the woofers anchored to by baffle by the magnet assembly. C

- Bottom

Comment

-

Should have linked this, too . . .

- Bottom

Comment

Comment