This is my first major woodworking project, so I need some help, and thought this would be the best place to ask. I'm getting ready to assemble my subwoofer end table, and I wondered what the best strategy is for getting it all glued up square and straight? Should I use screws to provide my clamping pressure, and then remove them when finished? The screw holes will later be covered by trim panels, so this is definitely an option, except for the top plate. How should I attached the top plate? Is a simple bead of PVA glue acceptable around the top rim of the rest of the box, or does it need dowel pins or some other joining method? What order should I glue the pieces? Braces? How many at a time? Should all the internal joints/seams be caulked after glued for extra strength/sealing? With what - liquid nails? Silicon?

The box is a down-firing design made from 18mm baltic birch ply, has a decent amount of internal bracing, and the bottom baffle is 2 layer thick; plate amp on the back side.

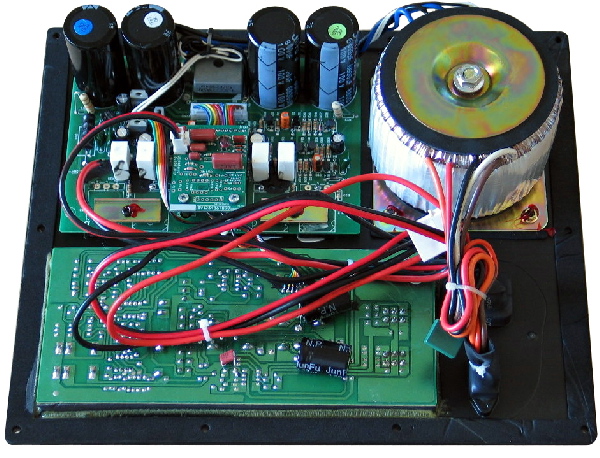

Here's a picture from a dry-fit last night (sans bracing and trim panels):

Thanks for helping the n00b!

-- Cameron

Edit: I've got 2 36" Irwin clamps, 6 12" Irwin clamps (almost useless in this application, and 1 band clamp.. I think I may need more clamps for this piece, but how far can I get with only these? What else should I get?

The box is a down-firing design made from 18mm baltic birch ply, has a decent amount of internal bracing, and the bottom baffle is 2 layer thick; plate amp on the back side.

Here's a picture from a dry-fit last night (sans bracing and trim panels):

Thanks for helping the n00b!

-- Cameron

Edit: I've got 2 36" Irwin clamps, 6 12" Irwin clamps (almost useless in this application, and 1 band clamp.. I think I may need more clamps for this piece, but how far can I get with only these? What else should I get?

... never tried it on speaker carcasses though.

... never tried it on speaker carcasses though.

Comment