Hi,

It's been a while but I wanted to build something.

When you are bussy outside you want music on the background and you don't always have a radio and/or power available.

So the goal is a portable speaker with a high efficiency, since it will also be powered by a battery, or DC voltage input.

The battery is available from my electric mountainboard I build.

I wil add a small fm-radio witch will also be able to play with bleutooth.

Of course I will also ad a mono audio amp 100W. Both from Banggood. Don't know if it will sound good, we will find out.

The fm-radio is on 5V DC so i'll need to a 5V regulator since the amp will run on 12-16V.

High efficiency, so a MTM speaker.

For the mid driver I went with a Peerless/Tymphany SDS P830855-8

The tweeter is a SB Acoustics SB26STCN-C000-4

I went for a ported enclosure.

Tuned at 54.5 Hz, with a f3 of 48Hz

x,max at 12W for one speaker

Volume is approximately 10l

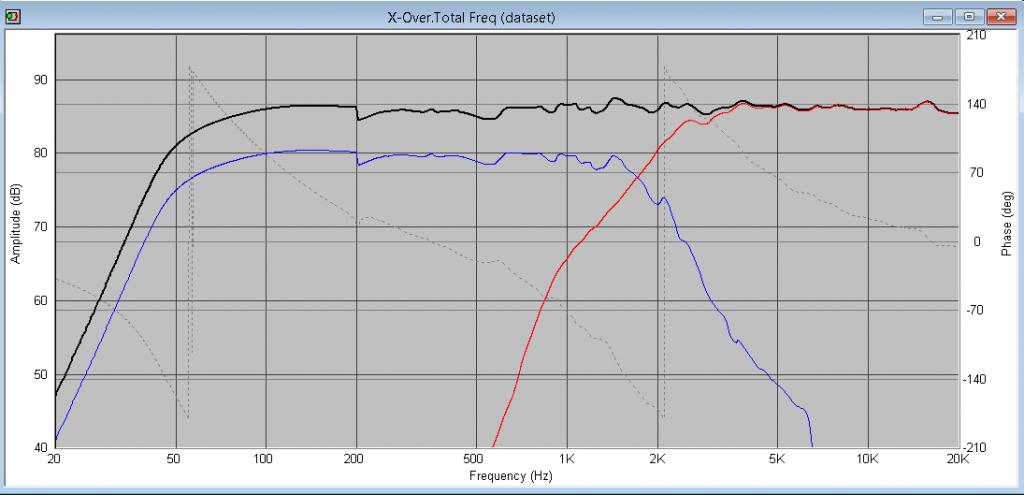

X-Over:

Crossed at around 2100Hz.

Freq. responce:

It's been a while but I wanted to build something.

When you are bussy outside you want music on the background and you don't always have a radio and/or power available.

So the goal is a portable speaker with a high efficiency, since it will also be powered by a battery, or DC voltage input.

The battery is available from my electric mountainboard I build.

I wil add a small fm-radio witch will also be able to play with bleutooth.

Of course I will also ad a mono audio amp 100W. Both from Banggood. Don't know if it will sound good, we will find out.

The fm-radio is on 5V DC so i'll need to a 5V regulator since the amp will run on 12-16V.

High efficiency, so a MTM speaker.

For the mid driver I went with a Peerless/Tymphany SDS P830855-8

The tweeter is a SB Acoustics SB26STCN-C000-4

I went for a ported enclosure.

Tuned at 54.5 Hz, with a f3 of 48Hz

x,max at 12W for one speaker

Volume is approximately 10l

X-Over:

Crossed at around 2100Hz.

Freq. responce:

Comment