Hi

To get a more decent sound for the TV in the living room we have decided that we want a pair of real speakers.

After some research I have found that the In-Khan-Neatos is looking like a good option.

The speakers will be placed on each side of the TV, quite close to the TV. The height of the front grill will be exactly the same as the height of the TV, so that the speakers should look like they are a part of the TV.

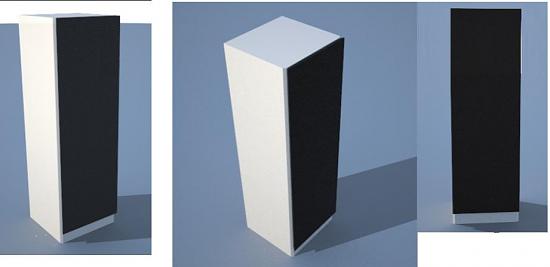

To make this look resonable good I'm thinking about a design like this:

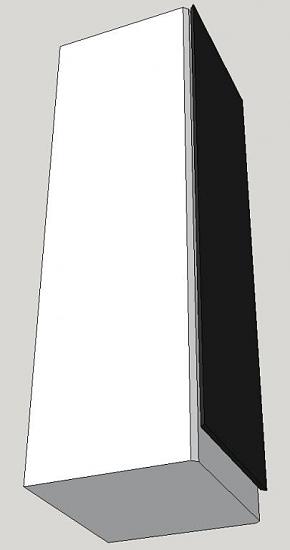

After looking at the TV-set, checking some other threads and done some calculation I think that 27" * 8 1/2" * 8" (h/w/d) is good dimensions for the box (outside).

The baffel is a bit smaller than the original drawings, but as the crossover that I'm planning to use is in-wall, and these will be close to the TV - I can't see that it should do much difference.

I plan to make the box out of 1/2" MDF, meaning that the internal volume of the box will be approximate 22-23 liters.

I will start to put together the shopping chart for parts quite soon I think.

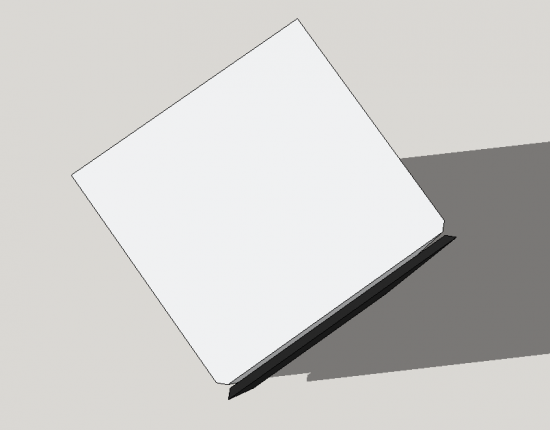

This was is the result:

To get a more decent sound for the TV in the living room we have decided that we want a pair of real speakers.

After some research I have found that the In-Khan-Neatos is looking like a good option.

The speakers will be placed on each side of the TV, quite close to the TV. The height of the front grill will be exactly the same as the height of the TV, so that the speakers should look like they are a part of the TV.

To make this look resonable good I'm thinking about a design like this:

After looking at the TV-set, checking some other threads and done some calculation I think that 27" * 8 1/2" * 8" (h/w/d) is good dimensions for the box (outside).

The baffel is a bit smaller than the original drawings, but as the crossover that I'm planning to use is in-wall, and these will be close to the TV - I can't see that it should do much difference.

I plan to make the box out of 1/2" MDF, meaning that the internal volume of the box will be approximate 22-23 liters.

I will start to put together the shopping chart for parts quite soon I think.

This was is the result:

) fit tightly together.

) fit tightly together.

Comment